- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

Brand: Goyal

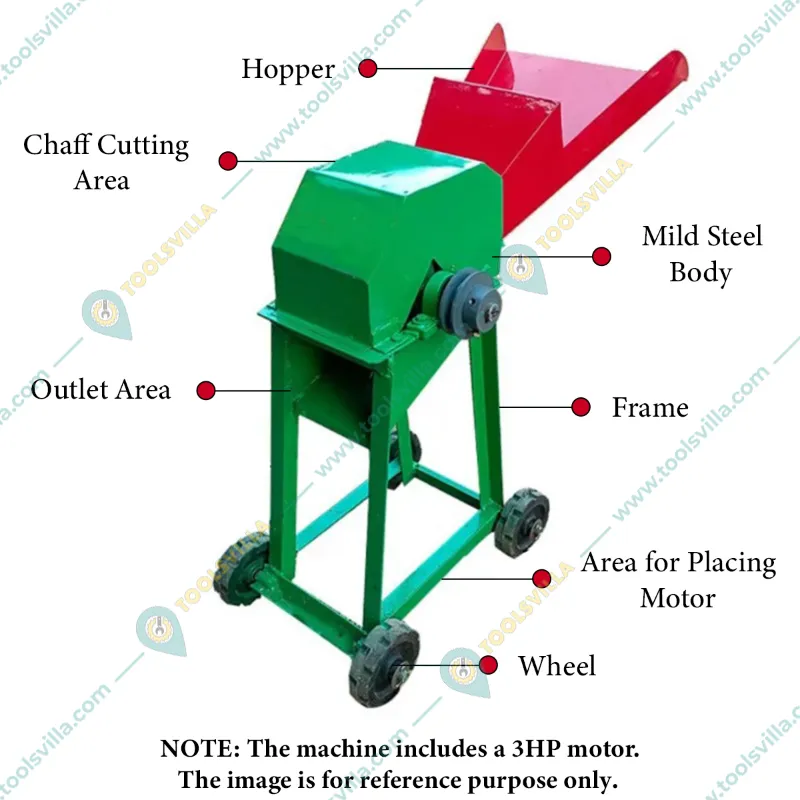

Heavy Duty Chaff Cutter/Grass Cutter Machine 800 Kg per hr, with 3 HP Motor

SKU: TI-HD-12282

₹20155 (Including GST)

Get extra ₹302 Discount (On Checkout)

Delivery By: Apr 10 - Apr 12

Delivery By: Apr 10 - Apr 12

Qty:

Easy Return

& Refund

Quality

Assurance

Trusted

Delivery

After Sales

Assistance

Buyer

Protection

Short Description

Heavy Duty Chaff Cutter/Grass Cutter Machine for Straw, Corn Stalk, Sugarcane Stalk

3HP Single Phase Motor

Cutting Capacity 800 kg/hr

Country of origin: India

Description

The Chaff/Grass Cutter is a device used for cutting hay, straw and other plant products for the purpose of preparation of animal fodder. This device automates the fodder preparation process and reduces the labour required in preparing fodder for animal. The machine cuts the raw materials which are used for fodder into small uniform pieces which aids digestion in cattle and livestock and prevents them from rejecting any part of their meal. The machine is equipped with a 1 HP single phase electric motor, has 3 high quality cutting blades (2 moving + 1 fixed) which helps in achieving the cutting capacity of 800 kilos per hour.

Features

:- Easy Operation and Maintenance: The chaff cutter is user-friendly with intuitive controls and clear instructions. Its design facilitates easy cleaning and maintenance, making it suitable for busy farmers who require efficient equipment.

- Powerful Motor: The chaff cutter is equipped with a powerful 3HP motor which makes it perfectly suitable for carrying out high volume fodder cutting tasks with ease.

- Versatility: This machine is versatile enough to handle various applications on both small and large farms. It can efficiently cater to the feeding needs of cattle, horses, goats, and other livestock.

Specification

:- Brand: Goyal

- Material : Mild Steel

- Weight (Approx.) : 82 kg

- Motor Power : 3 HP

- Phase : Single

- Power Source : Electric

- Voltage : 220 V

- Rated Power : 2.25 kW

- Power Consumption : 2.25 Unit/hr

- Total Blades : 3 (Two movable and one is fixed)

- Blade Material : Carbon Steel

- Output Capacity : 800 Kgs/hr

Note: This machine comes with a 3 HP motor. The images are for reference purpose only.

Usage

:1. Preparation and Setup:

- Location: Choose a flat, stable surface for the chaff cutter. Ensure that the area is clear of any obstacles or flammable materials.

- Power Supply: The user needs to connect the motor to a suitable power source in order to begin the fodder cutting operations.

- Safety Gear: Wear appropriate safety gear, including gloves, goggles, and ear protection, as operating machinery can be noisy and potentially hazardous.

2. Loading Material:

- Prepare the material (straw or hay) you wish to cut. It should be dry and free from foreign objects like stones or metal pieces.

- Feed the material into the hopper of the chaff cutter slowly and steadily. Avoid overloading the machine as this can cause jams or damage.

3. Starting the Machine:

- Turn on the power switch of the motor-operated chaff cutter.

- Allow the machine to reach its full operational speed before feeding in more material.

4. Cutting Process:

- As you feed material into the hopper, monitor its progress through the cutting mechanism.

- Adjust your feeding speed based on how quickly the machine processes the material; do not force too much at once.

5. Collecting Chaff:

- The cut chaff will exit from a designated outlet. Position containers or bags underneath this outlet to collect the chopped material efficiently.

- Ensure that no one stands directly behind or near this outlet during operation.

6. Shutting Down:

- Once you have finished cutting, turn off the motor using its designated switch.

- Wait for all moving parts to come to a complete stop before attempting any maintenance or cleaning.

Maintenance:

- Regular Inspections: Conduct regular checks on the chaff cutter parts. Pay particular attention to bolts and nuts; if any are loose, tighten them immediately to prevent operational issues.

- Lubrication: Every part of the chaff cutter requires lubrication. Clean the components thoroughly before adding lithium grease. Ensure that the gearbox is lubricated with oil every season, while the main bearing should be lubricated at least once a year.

- Dust Removal: When adding lubricating oil, it is crucial to remove any dust or debris to avoid contamination that could impair functionality.

- Wear and Deformation Checks: Regularly check all parts for signs of wear or deformation. If any issues are identified, replace those parts promptly to maintain safe operation.

Applications

:- Fodder Preparation & Nutritional Enhancements: The Chaff cutter helps in the preparation of fodder for animals. The materials are cut into uniform pieces which retain the required nutrients in it.

- Time & Labor Savings: This machine not only helps in fodder preparation but also saves a lot of time by automating the process of cutting fodder and saving both time and labor.

- Waste Reduction: It helps in efficient waste management as no plant product is left out as waste. They are utilized by converting them into fodder for cattle.