Brand: Generic (Imported)

Heavy Duty Stone Type Flour Mill for Feeding Cattle, 30 kg per hr

SKU: SD-RLX-21248

₹19560 (Including GST)

Get extra ₹293 Discount (On Checkout)

Out of Stock

Easy Return

& Refund

Quality

Assurance

Trusted

Delivery

After Sales

Assistance

Buyer

Protection

Short Description

Disc Mill Pulverizer for Feeding Cattle

30 kg per hr Production Capacity

3 HP Copper Coil Motor

3 unit per hr Electricity Consumption

30 kg per hr Production Capacity

3 HP Copper Coil Motor

3 unit per hr Electricity Consumption

Country of origin: China

Description

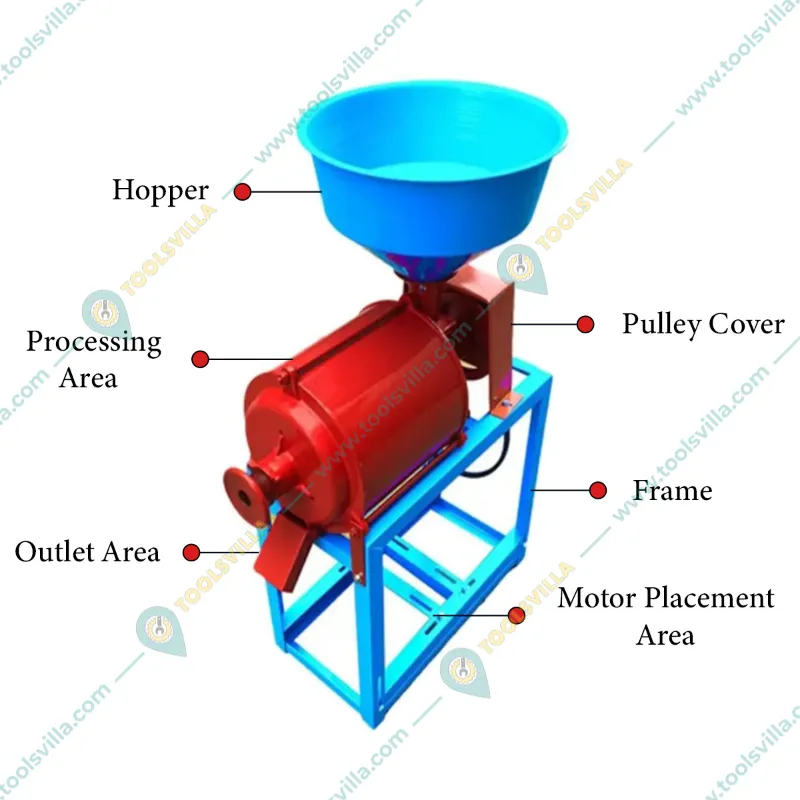

A flour mill designed for cattle feeding is a specialized machine used to grind grains and other feed materials into fine powder or flour, which is suitable for animal consumption. These mills are essential in agricultural and farming operations, particularly for small-scale farms or home use, as they allow farmers to process their own feed efficiently and cost-effectively.

Features

:- Grinding Mechanism : The primary feature of a stone type flour mill is its grinding mechanism, which typically consists of two stones that rotate against each other. This design allows for the fine grinding of grains, which is essential for creating a suitable feed texture for cattle. The stones can be made from natural materials or artificial composites designed to mimic traditional stone.

- Production Capacity : The production capacity of the flour mill is another vital feature. A typical stone type flour mill can process 30 kg per hour.

- Motor Power : The Stone type flour mills is equipped with a 3 HP electric motor. This motor provides ample power for carrying out various grinding tasks.

Specification

:- Brand: Generic (Imported)

- Motor Power : 3 HP

- Motor Winding : Copper

- Roller Speed : 1300 RPM

- Jali : 1

- Blade Material : Stone Type

- Production Capacity : 30 kg per hr

- Voltage : 220 V

- Phase : Single

- Electricity Consumption : 3 unit/hr

- Dimension (L x W x H) : 570 x 520 x 320 mm

- Weight : 53 kg (Approx.)

Usage

:- Prepare your grains : Before grinding, make sure your grains are clean and dry. Remove any debris or stones that may damage the mill.

- Add grains to the hopper : Pour the grains into the hopper, making sure not to overfill it.

- Start the mill : Turn on the mill and let it run for a few seconds to ensure it is functioning properly.

- Monitor the grind : Check the grind size and texture regularly to ensure it meets your needs. Adjust the grind setting as needed.

- Collect the flour : Once the grinding process is complete, collect the flour in a container and store it in an airtight bag or container.

Maintenance :

- Daily Cleaning : After each use, unplug the mill and remove any leftover flour. Use a brush, vacuum, or cloth to clean the grinding chamber.

- Regular Intervals : Check and lubricate the moving parts regularly according to usage. For frequent users, this may mean every few weeks, while occasional users can lubricate monthly.

- Replacement Schedule : Follow the manufacturer's recommendations regarding how often to replace the grinding discs. Depending on usage, this might be every few months to annually.

support@toolsvilla.com

support@toolsvilla.com Become a Seller

Become a Seller Download App

Download App Track Order

Track Order