- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

Brand: Generic (Imported)

Electric Manual Delta Foil Sealer 90mm, 200W

SKU: DK-SE-08

₹6499 (Including GST)

Get extra ₹97 Discount (On Checkout)

Delivery By: Mar 19 - Mar 21

Delivery By: Mar 19 - Mar 21

Qty:

Easy Return

& Refund

Quality

Assurance

Trusted

Delivery

After Sales

Assistance

Buyer

Protection

Short Description

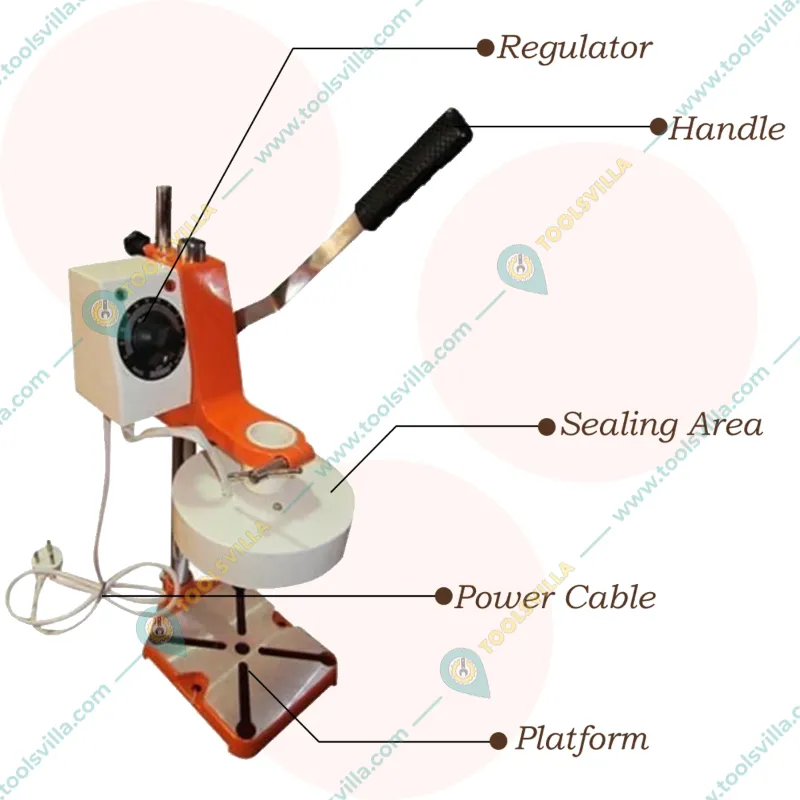

Electric Manual Delta Foil Sealer 90mm

Sealing Diameter Max : 90 mm (Plastic Material only)

200 Watt, 240 AC Voltage

Country of origin: China

Description

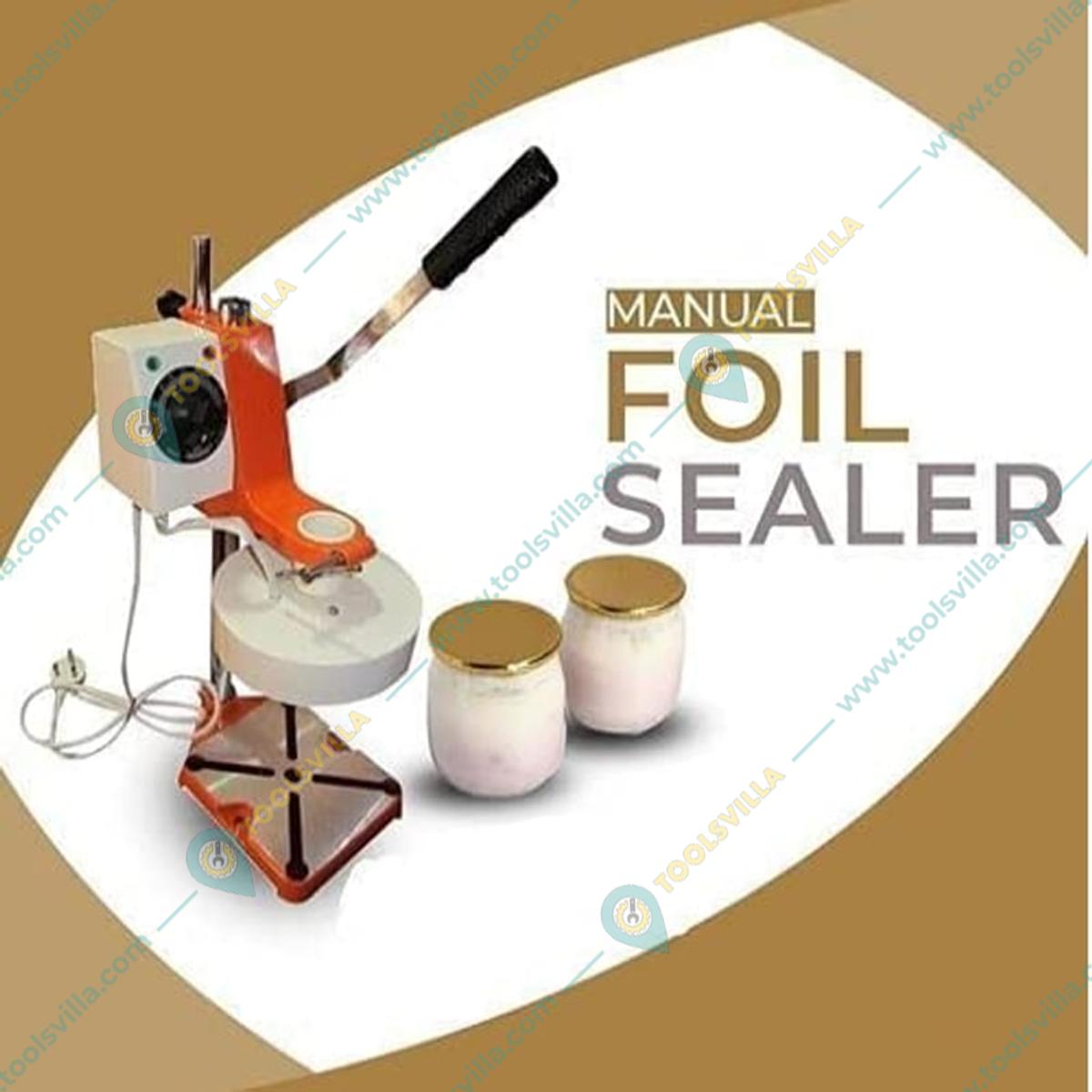

This Electric Manual Delta Foil Sealer 90mm, 200W is a specialized sealing device designed for the effective sealing of aluminum foils on various types of containers such as cups, cans and bottles. It is widely used for sealing companies, food packaging companies, small factories, food industries, and other food enterprises.

Features

:- For pilfer evident and leak-proof sealing of aluminium foils on cups, cans, bottles, plastic containers and trays.

- Height adjustability and provision for heat control.

- Strong cups, cans and bottles can be sealed without extra attachments. Flimsy Cups and trays require extra support at the bottom of the neck, otherwise, the cup/neck may be crushed during the sealing operation

- Designed to be space-efficient, making it suitable for small businesses or home use.

Specification

:- Brand: Generic (Imported)

- Weight (Approx.) : 5 kg

- Model No. : FS-1045 Delta

- Sealing Diameter Max : 90 mm (3.5 inch)

- Power : 200 W

- Voltage : AC 240

- Height of Containers : 0 to 170 mm (0 to 7 inch)

- Dimension (L x W x H) : 460 x 170 x 250 mm

- Weight : 5 Kgs (Approx)

Note : This machine is used for Plastic material only like plastic cups, Plastic glasses

Usage

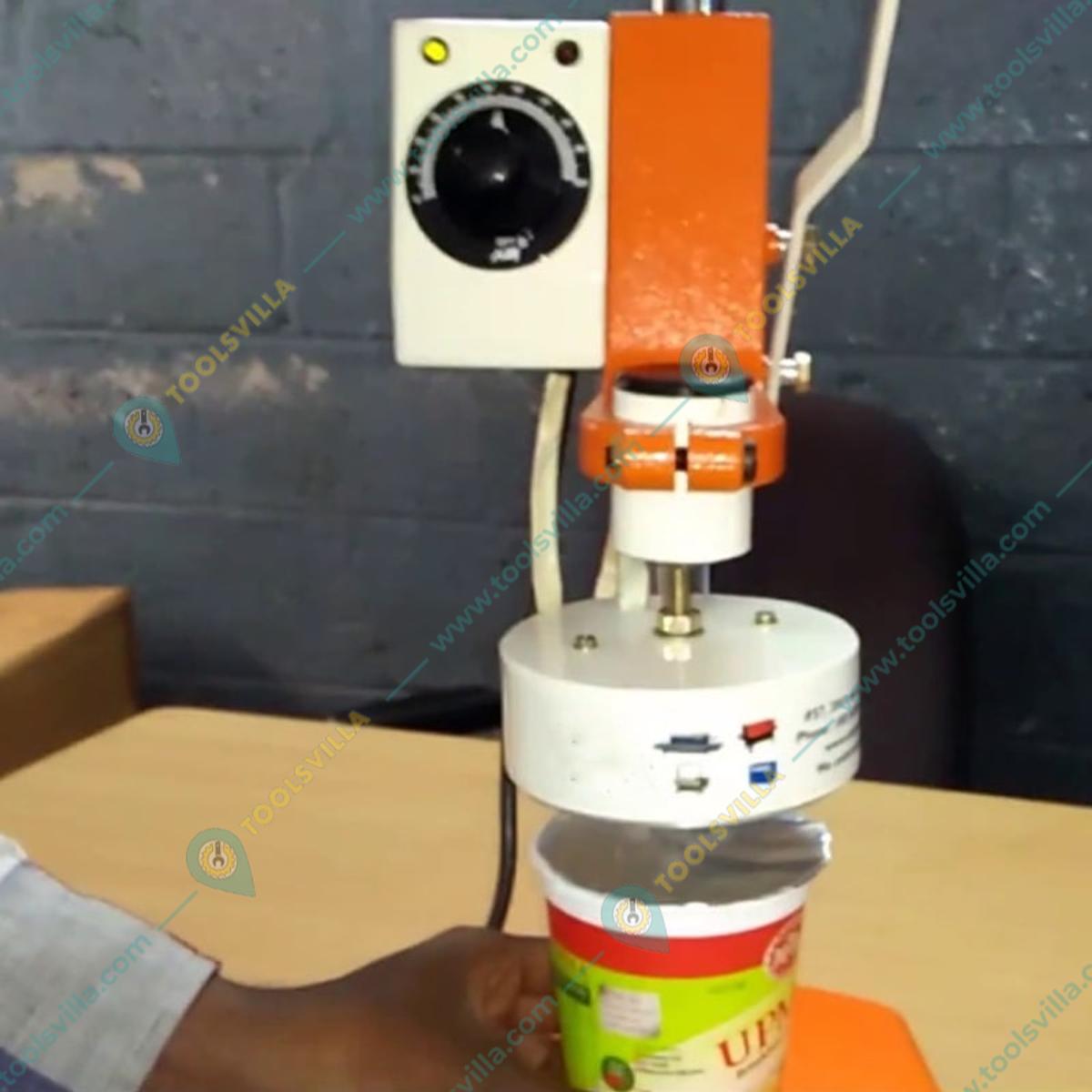

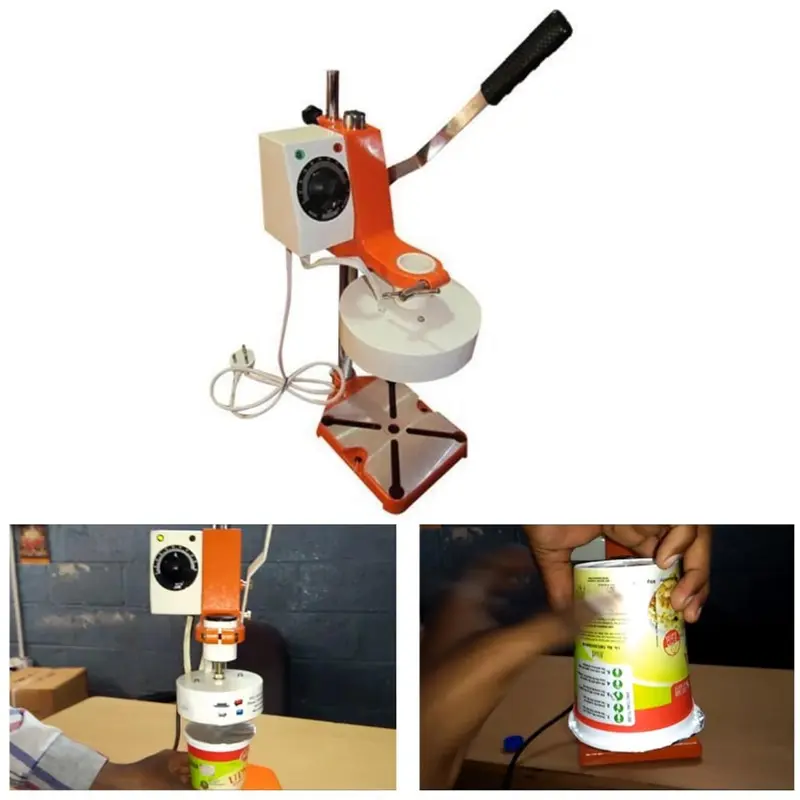

:- Preparation of the Work Area : Ensure a clean and organized workspace to operate the machine.

- Machine Setup : Connect the machine to a suitable power source, ensuring that the voltage is compatible with the device specifications.

- Loading the Product : Place the product securely on the designated platform of the sealing machine. Adjust the positioning to ensure that the foil covers the opening of the container entirely.

- Sealing Process : Close the sealing lever firmly, applying consistent pressure to ensure a proper seal.

Maintenance :

After using the machine needs to check the temperature and pressure settings to ensure they are within the recommended range and clean the sealing jaws with a soft cloth and a non-abrasive cleaning solution. To the long life of your machine sealing mechanism.

Applications

:- Beverages : It is also suitable for sealing beverage containers, such as cups or bottles, to ensure that they remain sealed until opened by the consumer.

- Cosmetics : The machine can be employed to seal cosmetic products in jars or tubes, maintaining hygiene and preventing leakage during transportation.

- Food Packaging : One of the most significant applications of the Electric Manual Delta Foil Sealer is in the food industry. This is crucial for preserving the shelf life of perishable items such as snacks, dried fruits, and vacuum-packed meals.

- Pharmaceuticals : It is utilized in the pharmaceutical industry to seal medicine containers, preventing contamination and preserving the integrity of the products.